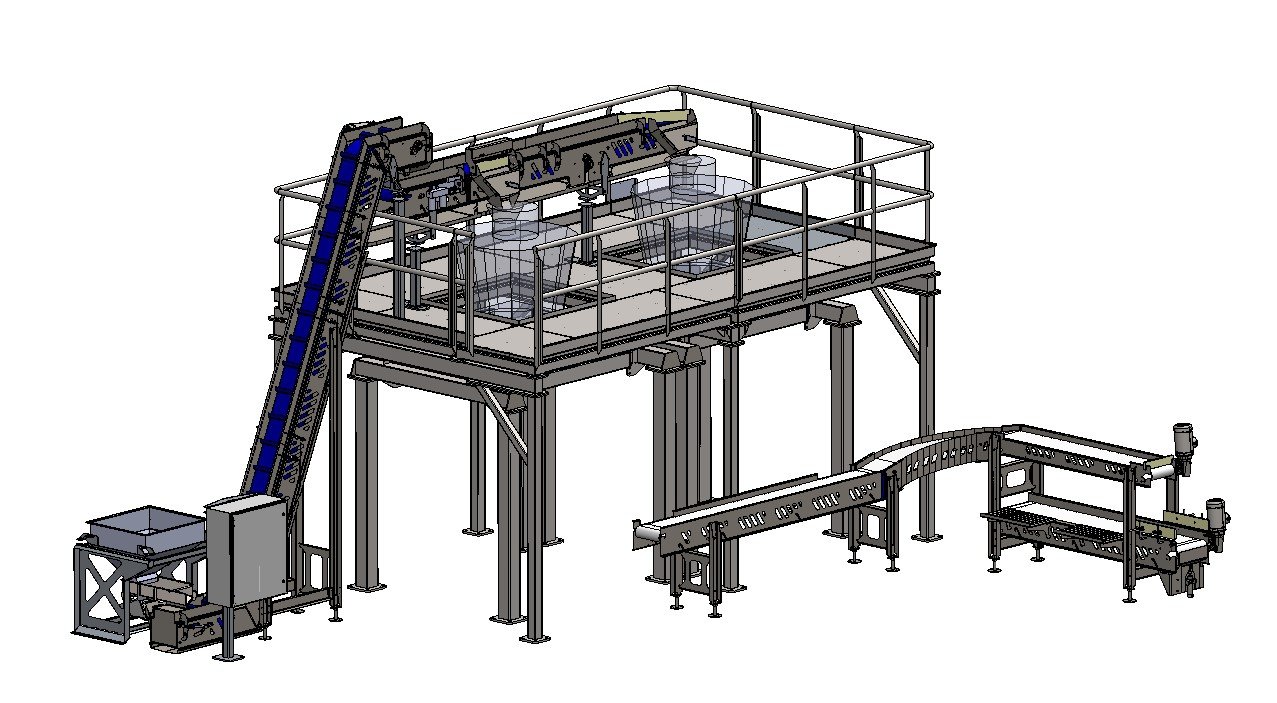

PACKAGING MEZZANINES

3D CAD LAYOUT OF STAINLESS STEEL MEZZANINE / CONVEYORS

Stainless Steel Mezzanines to connect processes and equipment. Our team will design around existing equipment and facilities layout to build a mezzanine tailor made to your space. We can incorporate your process and batch equipment into the support system. We commonly accommodate the following types of equipment: Scales / Weighers, Vibratory Feeders, Linear motion / Fastback conveyors, bucket elevators, magnetic separators, metal detectors/ x-ray.

Our process begins in SolidWorks 3D cad. Every mezzanine system and component is computer designed for maximum efficiency and quality. By leveraging cnc technology, we can maintain design fidelity and deliver accurate systems on time. If changes are needed down the road to accommodate new processes or equipment, we can update the design, and supply accurate change parts quickly. No remeasuring or guess work. Just accurate updates done right the first time.

Contact us today to get a free quote.

DECKING OPTIONS:

Diamond Plate

Anti-Slip HDPE Composite decking

Fabricated Tread Plate

Open Profile - Washdown*

*Can require site welding

SURFACE FINISHES:

MILD STEEL / POWDERCOAT

Effective solution for dry processing environments

Highly aesthetic uniform finish

Excellent Price / Performance Ratio

Recommended for pre-packaged items

(Individual wrapped candy etc.)

STAINLESS LEVEL 1 - Mill Finish

SS304 - MILL FINISH

Cost Effective Structural Finish

Raw / Production Steel Finish

Excellent Price / Performance Ratio

Great For Structural Components

Reduced Corrosion Resistance over mild steel

STAINLESS LEVEL 2 - Glass Bead Blasted

SS304 - GLASS BEAD FINISH

Food Grade Industrial Finish

Uniform blasted finish

Great corrosion resistance

Easy to clean

STAINLESS LEVEL 3 - #4 Grained

SS304 - #4 GRAINED FINISH

High Quality Aesthetic Finish

Excellent Cleanability

120 Grit Standard

STAINLESS LEVEL 4 - SANITARY

SS304 (GLASS BEAD FINISH)

OPEN PROFILE DESIGN / NO CLOSED SECTIONS

FULL WELD, NO GAPS

FREE OF SLAG, BURRS, SPATTER

SLOPED CONNECTION SURFACES

WELDED BOSSES FOR PLATE – PLATE SPACING

MEETS SANITARY / FULL WASHDOWN REQ.

STAINLESS LEVEL 5 - MARINE

ALL ITEMS FROM LEVEL 4

ADDS SS316L

HIGHEST LEVEL OF CORROSION RESISTANCE

TREATMENT OPTIONS:

Pickled / Passivated - Improves Corrosion Performance

Chemical Cleaning Process

Improves Performance Of All Finishes

Easy To Maintain

Can Be Used To Restore Oxidized Stainless

Electropolished

Size Limitations apply

Electrical Etching Process Removes Peaks / Valleys At Micro Level

Easy To Clean

Smooth / Reflective Surface

Can Increase Surface Tension

ADDITIONAL OPTIONS:

Kick Plate

Formed Kick Plate Standard On Diamond Plate Decking

Welded Kick Plate Available On Some Systems

Bolt On Kick Plate Available

Floor Drains

Channel Water Away From Components During CIP (Clean In Place)

Built in Grease Trap

Available Debris Keep Screen

Can Connect To Local Facility Drainage

Gutter System

Helps Collect Bulk Debris

Keeps Surrounding Floor / Equipment Clean

Designed To Aide CIP Systems

Conduit / Piping Routing System

Keeps Wiring Out Of Process

Protects Sensitive Connectors

Maintains Access To Critical Control Points

Reduces Site Time By Trades

Removable Railing

Adds Bulk Access For Equipment Installation

Great For Low Headroom Situations

Meets Osha Guidelines For Safety